BioEko Group

We are delighted to see knowledge regarding the re-use of the potential of PET plastic increasing year by year. This can be seen both in the increasingly conscious recovery of recyclables in households and in industry where solutions are being sought to replace other plastics with PET. The recycling potential of PET also makes products made from it a very favourable alternative to only seemingly environmentally harmless ‘competitors’.

As a manufacturer of PET film using recycled materials, we make every effort to raise awareness of environmental responsibility when using this raw material.

Ideal to secure packaging — TOGETHER, LET'S DE-MYSTIFY PLASTIC’S BAD REPUTATION!

WHY IS IT WORTH USING PET ?

PET plastic is used in the packaging industry as a substitute for the less environmentally friendly PP, PVC and PS films and for its economic benefits.

A common myth is that plastic packaging makes up the vast majority of waste. In fact, almost twice as much waste comes from cardboard and paper packaging! Furthermore, we hear about the ‘harmful’ effects of this plastic on the environment. In the case of the production of PET packaging, its impact on the environment is often believed to be not as dangerous as glass or aluminium.

PET, being a thermoplastic polyester, is characterised by high mechanical strength, dimensional stability and machinability and ductility. In addition, it offers the possibility of easy processing and virtually unlimited recycling, which increases its range of applications.

With the environment in mind, post-production waste is also used for the middle layer of multilayer films in the form of mesh from cut packaging. What does that mean in practice?

01.

THE USE OF MESH

The use of mesh can be a significant problem, mainly due to its dimensions, which occupy up to 45% of the surface of the output film. Thanks to the integrated in-line production system, the packaging is cut after shaping and the mesh is turned and ground in a single production line!

02.

WASTE-FREE NATURE

Due to the waste-free nature of the production and the closed-circulation process, the resulting packaging can also be used in direct contact with foodstuffs.

03.

RECYCLED RAW MATERIALS

In the near future, the degree of film utilisation involving maximum use of recycled raw materials should become a measure of progress in the rigid film thermoformed packaging segment.

HOW DO WE CARE FOR THE ENVIRONMENT?

- We purchase post-production plastic waste and PET bottles.

- We carry out manual and automatic selection by separating individual materials.

- We process waste on an automated production line.

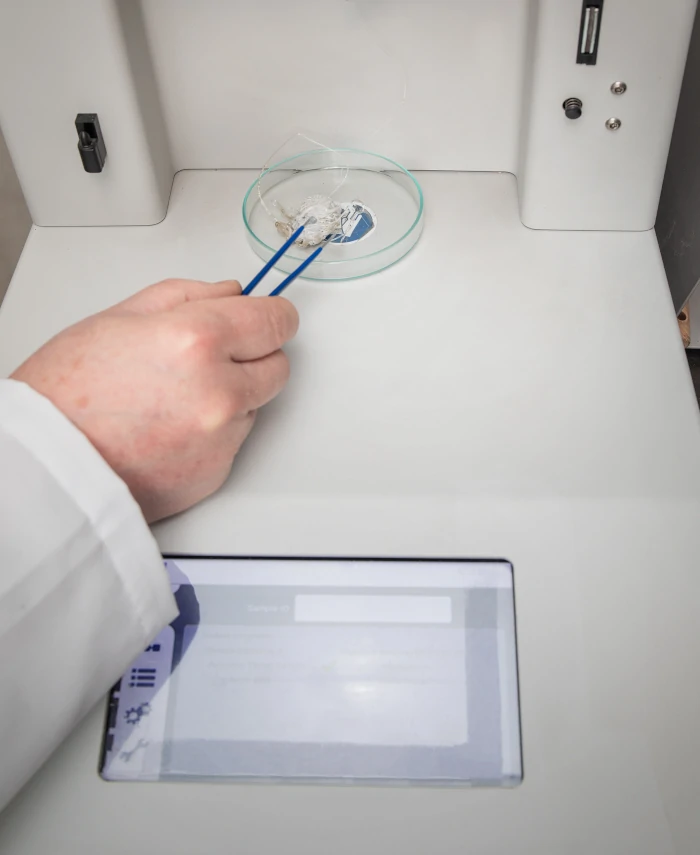

- We conduct quality control. In the interest of quality, we verify the final product produced in our laboratory!

- R&D project → we have developed an innovative method for recycling post-consumer waste made of PET.

Let’s remember that proper plastic management, segregation and reuse are safe for the environment.

1500

By recycling 1 tonne of PET bottles, we save 1.5 tonnes of CO2 emissions.

100 – 1000

Through recycling we reduce the decomposition time of a plastic bottle from 100-1,000 years to “0”.

CLOSED CIRCULATION

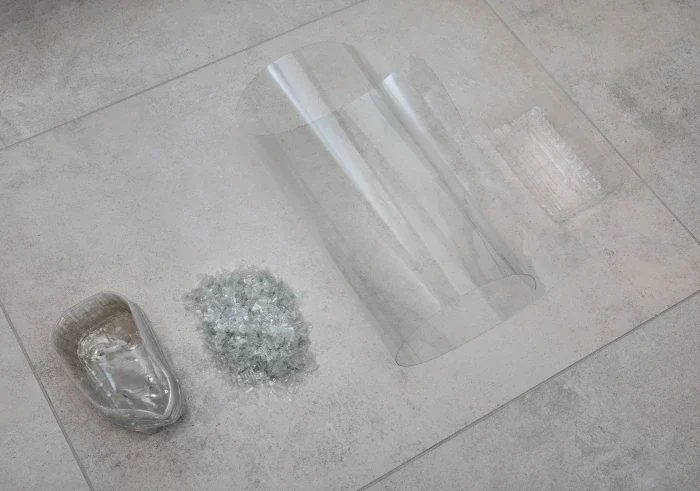

As a facility, we have recycler status. This allows us to source PET waste from the market and process it in virtually any form. The collected plastic is processed into flakes which is then an excellent raw material for producing rigid thermoforming film.

Thanks to the technologies we use, the film produced is certified to be used both for technical purposes and in the food industry. Ultimately, producers manufacture new packaging from it, which includes, for example, packaging for meats, cured meats, dairy products, vegetables and fruit.

WE GUARANTEE

PRODUCTION SAFETY

RESPONSIBILITY FOR MANUFACTURED PRODUCTS

COMPLIANCE WITH LEGAL AND SANITARY REQUIREMENTS

REDUCTION OF WASTE PRODUCTION

NEED MORE INFORMATION?

Send us an enquiry and our staff will get back to you as soon as possible!